China Laser Cleaning Machine Manufacturer

- Cleaning Efficiency (High)

- Artifact Damage (No Damage)

- Cleaning Way(Laser Non-contact)

- Consumable (Only Need Electricity )

- Cleaning Effect (Very Good High Cleanliness)

- Safety Environmental Protection (Pollution-free)

- Precision Cleaning (Accurate Control and High precision)

China Fiber Laser Cleaning Machine Manufacturer Hot Sale

The Fiber Laser Cleaning Machine can meet any of your cleaning needs.

A laser cleaning machine is the latest high-tech product. Easy to install, operate, easy to achieving automation. Plug-in power, turn on and start cleaning – without chemicals, media, dust, water.

Cleaning with no detergent, no media, no dust, no water. Autofocus can clean curved surfaces, gentle cleaning surfaces. Cleaning resin, oil stain, rust, coating materials, paints on the workpiece surface.

It is widely used in the cleaning of molds, the cleaning of metal surface coatings and welding points, the restoration and preservation of historical relics, and the removal of oil and grease stains on the surfaces of other objects

Features

- Non-contact cleaning, do not damage parts matrix.

- Accurate cleaning,the accurate position can be achieved. Accurate size-selective cleaning.no chemical cleaning solution, no consumables. Safety and environmental protection.

- The utility model has the advantages of simple operation, electrification, automatic cleaning by hand or with a manipulator, high cleaning efficiency, and time-saving.

- Laser cleaning system stable.

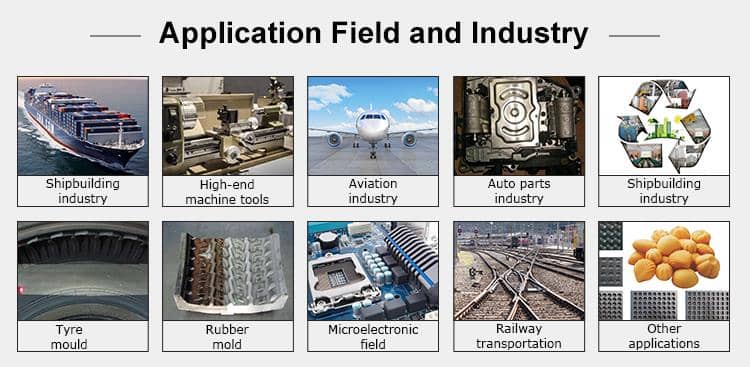

Applications

Applicable to Metal surface cleaning.

Removal paint of metal surface.

Stains cleaning on the surface

Surface coating cleaning

Pre-treatment of welding surface cleaning

Stone surface cleaning

Rubber mold residue cleaning

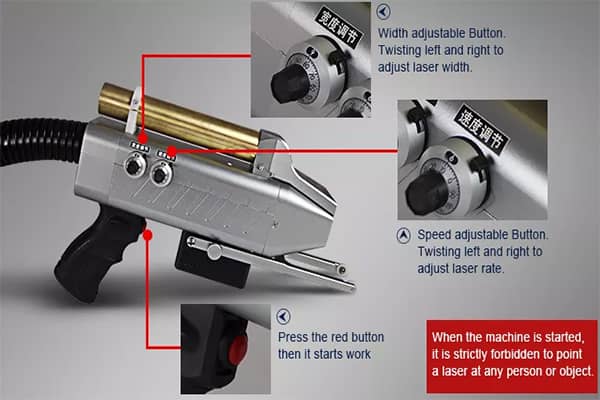

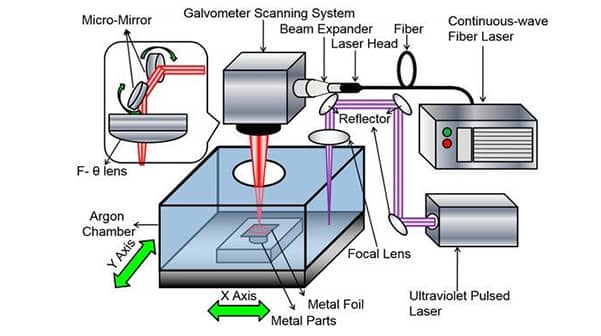

Introduction of laser cleaning head

1. With adjustable button twisting left and right to adjust laser width.

2. Speed adjustable button twisting left and right to adjust the laser power.

3. Press the red button it starts to work

4. Simple, easy to learn, easy to operate the characteristics of deep everyone’s favorite.

5. When the machine is started it is strictly forbidden to point a laser at a person and object.Except for work-pieces which need to be processed

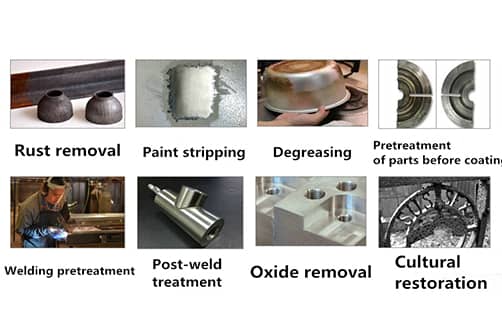

Cleaning Samples Under Different Laser Working Modes

Laser cleaning equipment is a new generation of surface cleaning high-tech products. Easy to install, operate and achieve automation. The operation is simple and no chemical reagent can be carried out. No medium. Dust-free, water-free cleaning, automatic focusing, surface fitting cleaning. Cleaning the advantages of high surface cleanliness. Able to remove resin from surfaces. Grease. Dirt. Rusting. Coating. coating. Paint and other stains.

The Features of Laser Cleaning

LASER CLEANING MACHINE IS A new generation of surface treatment of high-tech products, it’s easy to install, operate and achieve automation. Simple operation, power on, open the equipment, you can carry out no chemical reagent, no media, dust, no water cleaning, can manually adjust the focus, close to the surface cleaning, cleaning surface clean degree is high, can Remove Resin, paint, grease, dirt, dirt, rust, coating, coating and oxide layer, and widely used in the industry, including ships, auto repair, rubber mold, high-end machine tools, track and environmental protection

6 Advantages

1. Laser Non-contact.

2.No Damage.

3. High Cleaning Efficiency.

4.No Consumable (Only Need Electricity).

5. Very Good High Cleanliness.

6. Accurate Control and High precision.

7. Pollution-free (Safety Environmental Protection).

Applications of Laser Cleaning Machine

The customer may according to the different objects change the corresponding laser power laser speed and laser cleaning width

| Model: | JTC2000W |

| Laser power: | 2000W |

| Laser source type: | Fiber laser |

| Cooling mode: | Water cooling |

| Opration Mode: | Handheld |

| Machine size: | 1100mm*700mm*1150mm |

| Machine weight: | 220kgs |

| Laser head weight: | 2.5kgs |

| Scan width: | 10-80mm |

| Cleaning speed: | 5m3/h |

Laser cleaning machine is the latest high-tech product. Easy to install, operate, easy to achieving automation.. Plug in power, turn on and start cleaning – without chemicals, media, dust, water.

Cleaning with no detergent, no media, no dust, no water. Auto focus, can clean curved surface, gentle cleaning surface. Cleaning resin, oil stain, rust, coating materials, paints on workpiece surface.

Product Features

- The first laser cleaning machine with high fiber laser in China

- Substrate non-contact cleaning, without damage

- High precision cleaning, good precision of position cleaning,selective washing.

- Without any chemical cleaning fluid and no consume materials,safe and environment protecting.

- Simple operation,hand-hold clean or with a mechanical hand to clean .

- Good cleaning effect and save time

- Laser cleaning system is stability, almost no maintenance

Application

A Metal surface cleaning

B Removal paint of metal surface

C stains cleaning on the surface

D Surface coating cleaning

E Pre-treatment of welding surface cleaning

F Stone surface cleaning

G Rubber mold residue cleaning

Application Industry

Ship Industry,auto Parts, rubber Mold, high-end Machine,tire molde track,environmental Protection Industry and others.

Advantages

| Comparison Item | Laser-cleaning | Chemical-cleaning | Mechanical-cleaning | Dry ice | Ultrasonic |

| Cleaning Way | Laser, Non-contact | Chemical Cleaning Agents | Mechanical/Sandpaper, Contact | Dry ice, Non-contact Touch | Cleaner, Contact |

| Artifact Damage | No Damage | Damage | No Damage | No Damage | No Damage |

| Cleaning Efficiency | High | Low | Low | Middle | Middle |

| Consumable | Only Need Electricity | Chemical Cleaning Solution | Sandpaper, Grinding | Dry ice | Special Cleaning Fluid |

| Cleaning Effect | Very Good, High Cleanliness | In General, Uneven | In General, Uneven | Excellent, Not Even | Excellent,Clean Range Small |

| Precision Cleaning | Accurate Control and High precision | Uncontrolled, Accuracy is Poor | Uncontrolled | Uncontrolled, Accuracy is poor | Not Specified Range to Clean |

| Safety Environmental Pollution | Pollution-free | Chemical Pollution of the Environment | Pollution | No pollution | No pollution |

| Manual Operation | The operation is simple, hand-held or be automation | Complex process flow, high requirements for operators, should do measures to prevention pollution | Cost of artificial human very hard, take pollution prevention measures | The operation is simple, hand-held or automation | The operation is simple, but need to add manually consumables |

| Input Costs | The first time high input without consumables maintenance costs low | The first time low input material cost is extremely high | The first time high input, consumes the material artificial cost is low | The first time medium input and material cost is high | The first time low input, medium consumable cost |

Frequently Customer Enquiry

Most frequent questions and answers about the handheld laser cleaning machine

What is a laser cleaning machine and what can be done?

LASER CLEANING MACHINE IS A new generation of surface treatment of high-tech products, it’s easy to install, operate and achieve automation. Simple operation, power on, open the equipment, you can carry out no chemical reagent, no media, dust, no water cleaning, can manually adjust the focus, close to the surface cleaning, cleaning surface clean degree is high, can Remove Resin, paint, grease, dirt, dirt, rust, coating, coating and oxide layer.

laser cleaning machine can weld how much size of the product?

Strictly speaking, a laser cleaning machine can clean Resin, paint, grease, dirt, dirt, rust, coating, coating, and oxide layer on the surface of any substance -LRB-ships, auto repair, rubber mold, high-end machine tools, track

What materials can be removed by laser cleaning machine?

Resin, paint, grease, dirt, dirt, rust, coating, coating, and oxide layer materials.

Can large workpieces's oxide layer & Organic matter be Clean laser cleaning machine?

Yes, it 100% can be clean.

What is the cleaning effect of the laser cleaning machine?

Precision cleaning. Accurate location. Accurate size-selective cleaning: no chemical cleaning solution, no consumables. Safe and environmental, simple operation, power can be hand-held or with a manipulator to achieve automatic cleaning; cleaning efficiency is very high, save time, the laser cleaning system is stable.

Does the clean need to be secondary processing?

No need, once in place, clean and tidy. Accurate cleaning can realize the accurate position, the accurate size-selective cleaning.

What are the consumables for a laser cleaning machine?

Only Need Electricity.

Is it safe to use a laser cleaning machine?

Ensure that laser safety glasses are worn throughout the operation of the product. Laser safety glasses have laser wavelength protection selectivity, so please choose the laser safety glasses in line with the laser output band of the product. When the laser cleaning machine is powered on, it is forbidden to direct the laser output head to the human’s direction and to irradiate the surface of high reflective material (such as copper, aluminum, mirror stainless steel, etc.