High-precision fiber laser cutting machine

- Can cut all kinds of graphics on a flat plate.

- The precision is high, the slit is narrow, the heat-affected area is minimum, and the cutting surface is smooth and without burr.

- The cutting surface is smooth

- The laser cutting head does not touch the material surface and does not scratch the workpiece.

- The Cutting seam is narrow, the heat-affected zone is small, the local deformation of the workpiece is very small, and no mechanical deformation.

- Can be on steel, stainless steel, aluminum alloy plate, cemented carbide, and other materials of any hardness without deformation cutting.

- Low power consumption, no reaction gas, using Compressed air as a laser cutting auxiliary gas.

- Low consumption of consumables, long life, basic maintenance-free.

High precision fiber laser cutting machine Hot Sale

High-precision fiber laser cutting machines can be on steel, stainless steel, aluminum alloy plates, cemented carbide, and other materials of any hardness without deformation cutting.

Laser cutting machine the use of advanced structure design, machine tool performance of a fiber laser cutting machine, the application of international first-class numerical control system and fiber laser. The double-drive gantry structure is applied, the whole welding base is adopted, and the process vibration aging treatment after rough machining is used to eliminate the stress during welding and machining. It adopts screw guide rail transmission, high precision, one-time cutting molding, and no need for follow-up treatment. Greatly improve the processing efficiency; visual layout, close-fitting, and saving materials. Advanced technology can improve your company’s new product development speed, the fastest for you to recover the cost of equipment investment.

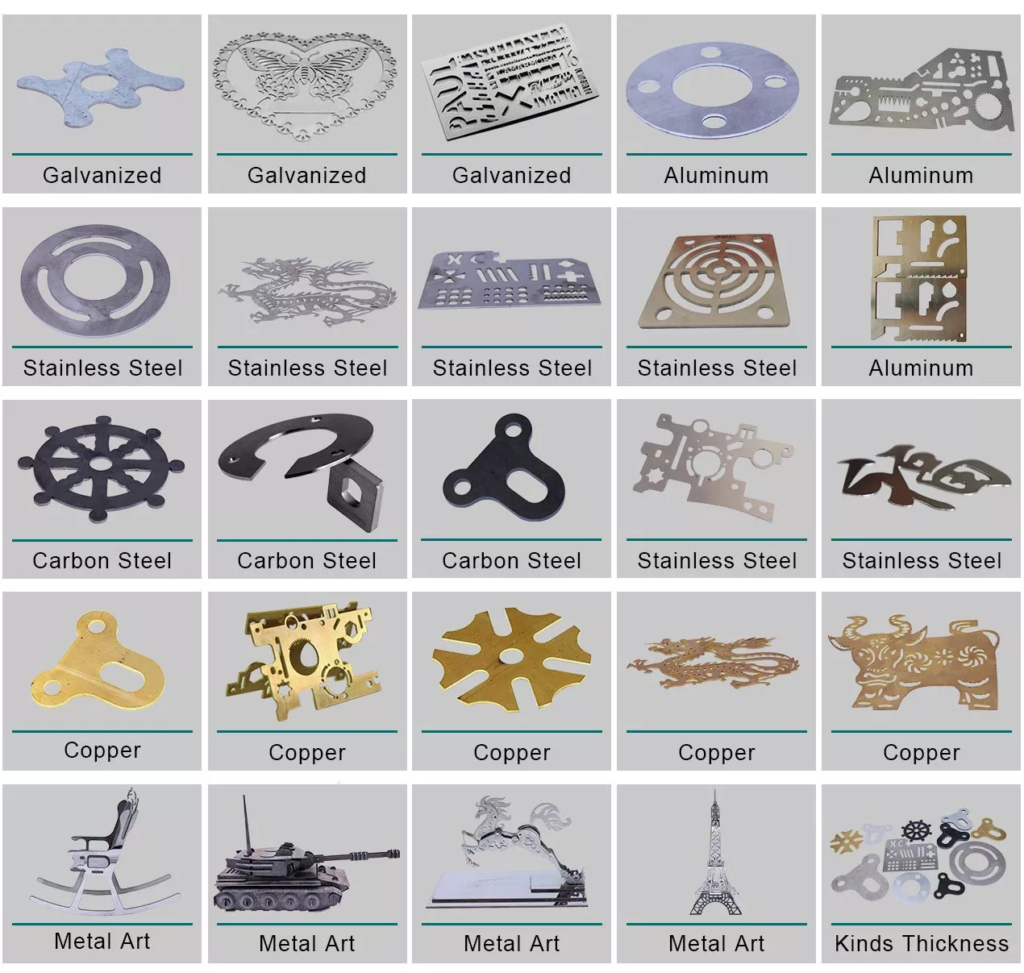

Widely used in sheet metal processing, advertising sign word production, mechanical parts, kitchen utensils, metal crafts, saw blades, hardware, and other industries. Can also be used for carbon steel, stainless steel, aluminum alloy, carbon steel, copper, titanium, and other metal cutting.

Features

- It can cut all kinds of graphics in plane plate with high precision, narrow slit, minimum heat affected zone, smooth cutting surface without burr, laser cutting head will not contact with material surface, do not scratch workpiece, narrow slit, small heat-affected zone, minimal local deformation of the workpiece, no mechanical deformation, good processing flexibility, can process arbitrary shapes, but also can cut pipes and other profiled materials, it can cut steel plate, stainless steel, aluminum alloy plate, hard alloy and other materials of any hardness without deformation, low power consumption, no reaction gas, using Compressed air as auxiliary gas in laser cutting has low consumption, long life and no maintenance.

Applications

Widely used in sheet metal processing, advertising sign word production, mechanical parts, kitchen utensils, metal crafts, saw blades, hardware, and other industries. Can also be used for carbon steel, stainless steel, aluminum alloy, carbon steel, copper, titanium, and other metal cutting.

4060 precision laser cutting machine

4060 precision laser cutting machine is an advanced structure design, machine tool performance of a fiber laser cutting machine, the application of international first-class numerical control system and fiber laser. The double-drive gantry structure is applied, the whole welding base is adopted, and the process vibration aging treatment after rough machining is adopted to eliminate the stress during welding and machining. It adopts screw guide rail transmission, high precision, one-time cutting molding, no need for follow-up treatment. Greatly improve the processing efficiency; visual layout, close fitting, saving materials. Advanced technology can improve your company’s new product development speed, the fastest for you to recover the cost of equipment investment. Widely used in sheet metal processing, advertising sign word production, mechanical parts, kitchen utensils, metal crafts, saw blades, hardware and other industries. Can also be used for carbon steel, stainless steel, aluminum alloy, carbon steel, copper, titanium and other metal cutting.

The material that can be cut by a precision laser cutting machine

Sheet metal, advertising sign word production, mechanical parts, kitchenware, metal crafts, saw blades, hardware and other industries. Can also be used for carbon steel, stainless steel, aluminum alloy, carbon steel, copper, titanium and other metal cutting.

The Features of a High-precision fiber laser cutting machine

It can cut all kinds of graphics in plane plate with high precision, narrow slit, minimum heat affected zone, smooth cutting surface without burr, laser cutting head will not contact with material surface, do not scratch workpiece, narrow slit, small heat-affected zone, local deformation of the workpiece is very small, no mechanical deformation, good processing flexibility, can process arbitrary shapes, but also can cut pipes and other profiled materials.

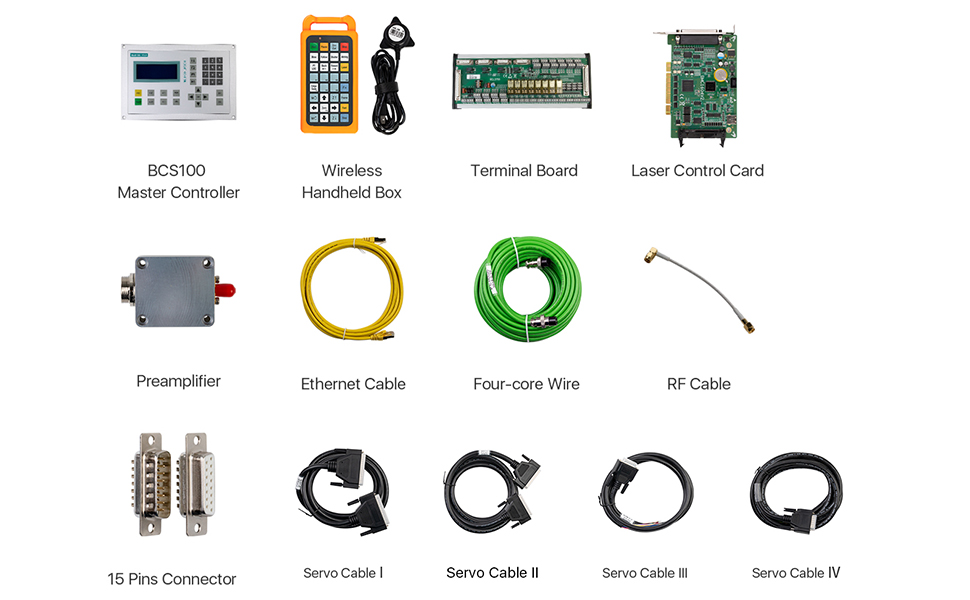

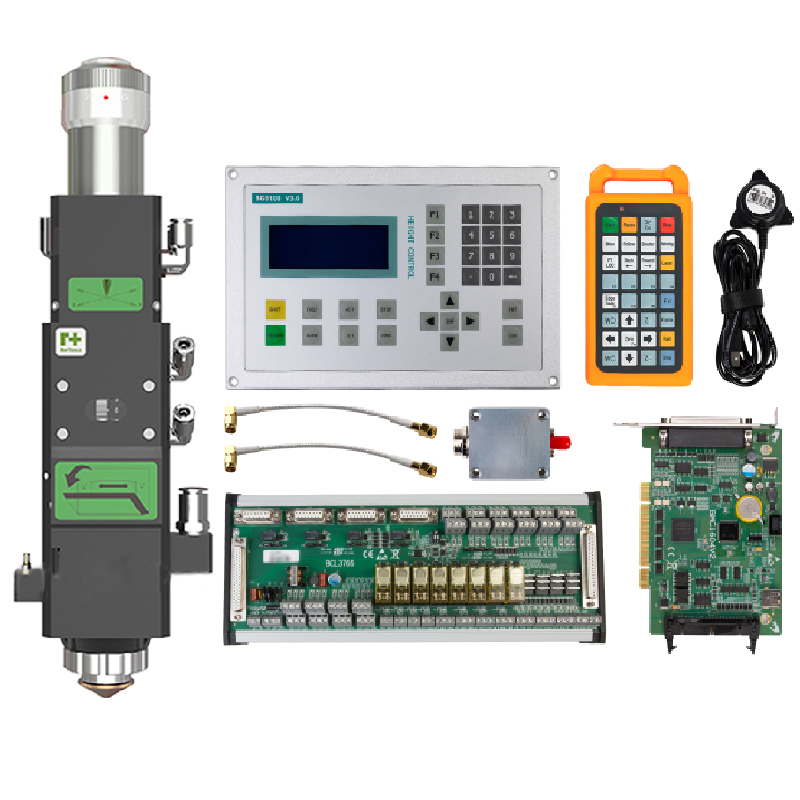

High-precision fiber laser cutting machine Accessories include.

1. CNC system

2.X/y 1/y 2/Z servo drive motor

3. High-precision screw rod

4. Z-axis screw.

5. Linear Guide rail

6. Laser source

7. Cutting head

8. Water Cooler

9. Pneumatic components

10. Electrical components

11. software

Technical parameters of laser cutting machine

No. | Project name | parameter |

1 | Type of equipment | 4060 |

2 | The wavelength of the laser | 1070nm |

3 | Output Power of the laser | Matching |

4 | Effective cutting area | 400mm*600mm 600mm*600mm 800mm*800mm |

5 | Cutting thickness (related to laser power) | Carbon Steel ≤18mm, stainless steel ≤8mm, aluminum alloy ≤6mm, copper ≤6mm; |

6 | Positioning accuracy | ≤±0.01mm |

7 | Repeat positioning accuracy | ≤±0.01mm |

8 | Speed of synthesis | ≤35m/min |

9 | Displacement acceleration | 0.5G |

10 | Machine tool bearing | 300KG |

11 | Demand for electricity | AC220V±5%/50Hz |

12 | Power consumption of the whole machine | 18KW |

13 | External dimension of cabinet | 1600*1700*2000(mm) |

14 | Weight of machine tool | 约1500KG |

15 | Support for graphics formats | dxf |

Cutting parameters of laser cutting machine

Because the cutting head and the laser model is not uniform, to 1500W as an example, the following parameters for reference only:

No. | Materials | Thickness(MM) | speed(m/min) | Auxiliary gas |

1 | Stainless steel | 1 | 35-45 | High pressure nitrogen(N2) |

2 | Stainless steel | 2 | 12-18 | High pressure nitrogen(N2) |

3 | Stainless steel | 3 | 4.5-5.5 | High pressure nitrogen(N2) |

4 | Stainless steel | 4 | 2.5-3.5 | High pressure nitrogen(N2) |

5 | Stainless steel | 5 | 1.5-2.0 | High pressure nitrogen(N2) |

6 | Stainless steel | 6 | 0.8-0.9 | High pressure nitrogen(N2) |

7 | Stainless steel | 8 | 0.2-0.3 | High pressure nitrogen(N2) |

8 | Carbon Steel | 1 | 16-20 | Oxygen(O2) |

9 | Carbon Steel | 2 | 7.8-8.3 | Oxygen(O2) |

10 | Carbon Steel | 3 | 4.6-5.2 | Oxygen(O2) |

11 | Carbon Steel | 4 | 2.5-3.0 | Oxygen(O2) |

12 | Carbon Steel | 5 | 2.0-2.5 | Oxygen(O2) |

13 | Carbon Steel | 6 | 1.7-2.0 | Oxygen(O2) |

14 | Carbon Steel | 8 | 1.2-1.5 | Oxygen(O2) |

15 | Carbon Steel | 10 | 1.0-1.2 | Oxygen(O2) |

16 | Carbon Steel | 12 | 0.8-0.9 | Oxygen(O2) |

17 | Carbon Steel | 16 | 0.5-0.7 | Oxygen(O2) |

18 | Aluminium | 1 | 25-35 | High pressure nitrogen(N2) |

19 | Aluminium | 2 | 7.5-9 | High pressure nitrogen(N2) |

20 | Aluminium | 3 | 4-5 | High pressure nitrogen(N2) |

21 | Aluminium | 4 | 2-2.5 | High pressure nitrogen(N2) |

22 | Aluminium | 5 | 0.9-1.3 | High pressure nitrogen(N2) |

23 | Aluminium | 6 | 0.5-0.7 | High pressure nitrogen(N2) |

24 | Aluminium | 8 | 0.2-0.25 | High pressure nitrogen(N2) |

Frequently Customer Enquiry

Most frequent questions and answers about the high-precision fiber laser cutting machine

What is a high-precision fiber laser cutting machine and what can be done?

A high-precision fiber laser cutting machine is a state-of-the-art cutting tool that uses a powerful laser beam to cut through various materials with high precision and accuracy. Unlike traditional cutting methods that rely on mechanical force, laser cutting machines use heat generated by the laser beam to melt and vaporize the material, resulting in a clean and precise cut. Fiber lasers are used in high-precision cutting applications such as manufacturing, aerospace, medical equipment, and electronics. Attached to a 4-axis or 5-axis machine, fiber lasers can perform cuts on complex shapes to an accuracy of up to 0.01mm. They are also versatile and can be used to cut a wide range of materials, including metals (e.g. aluminum, stainless steel, copper), plastics, and even wood. Some of the advantages of using a high-precision fiber laser cutting machine include: 1. Enhanced efficiency: The fiber laser cutting machines are capable of high-speed processing compared to other cutting technologies. This results in reduced processing times and increased production efficiency. 2. Improved accuracy: The accuracy of the fiber laser cutting machine is incredibly high, which ensures that parts or products produced have high precision. 3. Cost-effective: Fiber laser cutting machines require less maintenance and are more cost-effective compared to other cutting technologies. 4. Flexibility: They can cut, engrave, and mark a wide variety of materials with intricate shapes and patterns. The high-precision fiber laser cutting machine can be used to cut various products including automotive components, medical equipment, jewelry, consumer electronics, and much more. In conclusion, fiber laser cutting machines are a high-performance alternative for high-precision cutting applications.

High-precision fiber laser cutting machine can cut how much size of the product?

The size of the product that a high-precision fiber laser cutting machine can cut depends on the specific machine’s capabilities. Some machines are designed to handle smaller parts, while others can cut larger sizes. Generally, fiber laser cutting machines can cut through materials that are up to several inches thick. However, the size of the product that can be cut is not just influenced by the thickness of the material, but also by the maximum cutting area of the machine. Most high-precision fiber laser cutting machines have a cutting area of at least 1200 mm x 1200 mm (47 inches x 47 inches). However, there are some machines that can cut larger products with a cutting area of up to 1500 mm x 3000 mm (59 inches x 118 inches). Overall, the size of the product that a high-precision fiber laser cutting machine can cut depends on the specific machine’s capabilities, including the thickness of materials and the maximum cutting area.

What materials can high-precision fiber laser cutting machine cut ?

High-precision fiber laser cutting machines can cut metals such as steel, aluminum, brass, copper, and titanium. The precise and efficient nature of the fiber laser cutting process makes the technology perfect for a wide range of applications, from industrial manufacturing to artistic and decorative pieces.

Can large workpieces be cut by high-precision fiber laser cutting machine?

Yes, high-precision fiber laser cutting machines are capable of cutting large workpieces with precision and accuracy. The size of the workpiece that can be cut depends on the size of the machine’s cutting bed, but there are fiber laser cutting machines available with cutting beds that are large enough to accommodate even very large and bulky workpieces. Fiber laser cutting machines are known for their high power and precision, which allow them to cut through a variety of metallic and non-metallic materials, including steel, copper, brass, aluminum, and more, with great accuracy and speed. Laser cutting is often the preferred method for cutting large and thick metal workpieces due to its clean cuts, high productivity, and low operational cost.

What is the cutting effect of the high-precision fiber laser cutting machine?

The cutting effect of a high-precision fiber laser cutting machine is characterized by its high precision, accuracy, and clean cuts. Fiber laser cutting machines use a highly focused laser beam to cut through various materials, including metals and composites, with great precision and speed. The laser beam is produced by a fiber laser source, which generates a concentrated beam of light that can reach temperatures of up to tens of thousands of degrees Celsius, allowing it to melt and vaporize the material being cut. The cutting effect of a high-precision fiber laser cutting machine is characterized by its ability to make very narrow cuts, with a kerf width as small as a few microns for thin materials, which minimizes material waste and allows for more precise cuts. Moreover, it produces smooth edges with a high-quality finish, which eliminates the need for additional finishing processes such as deburring or polishing. The cutting effect of a high-precision fiber laser cutting machine can also be programmed to suit the requirements of specific materials and designs, making it a versatile cutting tool for a wide range of industrial applications.

Does it need to be reprocessed after cutting?

In most cases, a high-precision fiber laser cutting machine produces clean cuts without the need for reprocessing or additional finishing processes. This is because the laser beam used in fiber laser cutting machines produces highly precise cuts, with minimal heat-affected zones and minimal distortion. The result is a high-quality edge finish that often does not require additional processing, such as sanding, polishing, or deburring. However, the need for reprocessing may depend on the specific application and the materials being cut. For example, some materials may be more susceptible to edge burrs or roughness, which may require additional finishing steps. Additionally, if the cut edges need to be further machined or joined, they may require additional processing to ensure proper fit and function. Therefore, while a high-precision fiber laser cutting machine can produce clean cuts in many cases, the need for additional reprocessing may depend on the specific requirements of the application and the materials being cut.

What are the consumables for a high-precision fiber laser cutting machine?

The consumables needed for a high-precision fiber laser cutting machine may vary depending on the specific machine and the materials being cut. However, here are some common consumables that may be required: 1. Nozzles: The nozzle directs the laser beam onto the material being cut and helps to maintain a consistent beam focus. Over time, nozzles may become worn and need to be replaced. 2. Protective lenses: The protective lens is positioned in front of the cutting lens and helps to protect it from debris and splatter generated during cutting. Over time, the protective lens may become scratched or damaged and need to be replaced. 3. Cutting lenses: The cutting lens is the lens that focuses the laser beam onto the material being cut. Over time, the cutting lens may become dirty or damaged and need to be replaced. 4. Gas filters: Many laser cutting machines use gas (such as nitrogen or oxygen) to assist in the cutting process. Gas filters help to remove impurities from the gas supply and ensure consistent cutting performance.

Is it safe to use a high-precision fiber laser cutting machine?

High-precision fiber laser cutting machines are safe to use when proper safety measures are taken. These machines generate a high-powered laser beam that can cut through various materials, and as a result, there is a risk of injury if proper precautions are not taken. Here are some safety measures that should be taken when using a high-precision fiber laser cutting machine: 1. Eye protection: It is essential to wear appropriate eye protection such as laser safety glasses or goggles when operating a fiber laser cutting machine to prevent eye damage. 2. Proper ventilation: Laser cutting generates heat and fumes that can be harmful if inhaled. Ventilation systems should be in place to remove fumes and ensure a safe working environment. 3. Safety interlocks: The machine should have safety interlocks that prevent the laser from firing if the machine door or cover is open. 4. Training: Users should receive proper training on how to safely operate the machine and the potential hazards associated with laser cutting. 5. Maintenance: Regular maintenance of the machine, including cleaning and checking for any potential hazards, is crucial for safe operation. With proper safety measures and training, high-precision fiber laser cutting machines can be safely operated to achieve accurate and efficient cutting results.