China Handheld Laser Welding Machine Manufacturer

- 30 Times Faster than Mig and Tig Welding

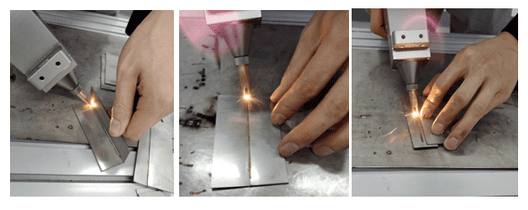

- The workpiece can be welded at any angle

- 24hrs Continuous Welding Capability

- Can weld long-distance, big workpieces.

- Longer Service Life

- Free Maintenance

- Easy Operation

Fiber Handheld Laser Welding Machine Hot Sale

The handheld laser welding machine can meet any of your welding needs.

Hand-held laser welding machines can carry out long-distance, large parts of the laser welding, welding heat affected area is small, will not cause workpiece deformation, blackening, backtrace problems.

and welding

Deep welding, solid welding, full melting. The convex part of the solution pool and the matrix joint have no depression phenomenon! Fast welding speed, 2-10 times faster than traditional welding, a machine can save at least 2 welders a year.

The advantage of the hand-held laser welding machine is that it can weld the products with larger size and longer welding length, such as water tank and stainless steel kitchen cabinet without putting these products on the worktable. In addition, to repair large mold, large-scale machinery can also achieve long-distance welding, do not take down the product can be welded.

Features

- Can quickly learn to operate, for you to save expensive technical labor costs! This product operation is simple and convenient, raw and experienced hands can be on the machine operation, for you to solve the technical talent difficult to recruit, technical talent high wages!

- The Worker is efficient and does not work tired! Hand-held rapid positioning welding, do not need to move the workpiece, just move the hand-held welding head can be fast welding, high working efficiency,

- Clean work, improve the image of the company! Hand-held laser welding machine in work, welding smokeless, no strong light, ultra-low noise, no matter the size of the workpiece, how complex can be welded, welding precision, meticulous.

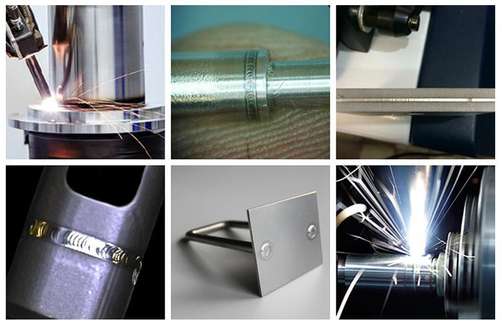

Applications

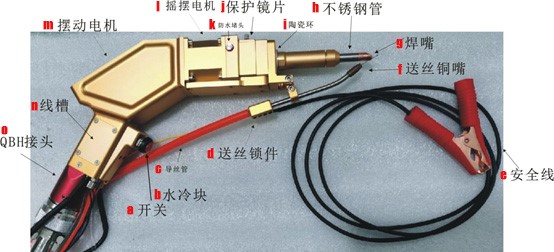

Introduction of hand-held welding Gun And Automatic Wire Feeder System

1.The internal design is smart, good interactive control system, expanding the tolerance range of processing parts and weld width.

2.The shape is light, the body engineering design method is adopted, the grip is comfortable, the control is easy and the operation is simple Easy to use.

3.The utility model has the advantages of multiple safety alarms, automatic light locking after removing the workpiece, and high safety

4.Beautiful Weld, fast speed, no consumables, no weld marks, no color change, no need to later grinding.

5. Can be equipped with a variety of angle nozzles to meet different product welding needs.

Welding Samples Under Different Laser Working Modes

This is a new type of metal welding technology, low technical requirements for technical workers, just a light grinding and light polishing can be out of exquisite effect, firm and reliable. It is a new welding method to reduce labor costs and increase production efficiency.

Fiber laser hand-held welding machine can weld 0.4-5.0 mm thick stainless steel, galvanized sheet, iron, copper, aluminum, and other metal materials.

The Features of Double Wobble Laser Gun

According to the different welding processes, customers can change the corresponding nozzle (yin angle, copper nozzle, Yang angle copper nozzle, wire delivery copper nozzle).

The focal length of the screw tube can be adjusted with a value of ± 10

6 Different Laser Control Modes.

1.Dot.

2.Line.

3.Circle.

4.Double-Circle.

5.Triangles.

6.Double Triangles.

Applications of Double Wobble Laser Head

The customer may according to the different welding craft change the corresponding nozzle (the shade angle Copper mouth, Yang Jiao copper mouth, send wire copper mouth) modes.

| Welding Mode | Descriptions |

|---|---|

| Dot Mode | Dot mod or we call it spot welding is a good at deep penetration welding, such as laser perforation, stich welding and cutting like a hand held laser cutter. |

| Line Mode | For butt welding, external corner welding and wire-feed welding. |

| Circle Mode | For welding thin plate (minimum 0.3mm or 0.12″) and 90 degrees corner welding. |

| Double Circle Mode | Enhanced circle mode, common use in various kinds of welding. |

| Triangle Mode | For all kinds of welding and wire-feed welding. |

| Double Triangle Mode | Enhanced triangle mode, for internal and external corner welding with nice fish scale pattern. |

Technical Parameters

| Laser Power Options | Material and Thickness | Gas |

|---|---|---|

| 1000W | Stainless Steel 1.5 (0.06″) | Ar |

| Carbon Steel 1.5 (0.06″) | Ar | |

| Galvanized Sheet 1.2 (0.047″) | Ar | |

| Aluminum 1.2 (0.047″) | N2 | |

| 1500W | Stainless Steel 2 (0.078″) | Ar |

| Carbon Steel 2 (0.078″) | Ar | |

| Galvanized Sheet 1.5 (0.06″) | Ar | |

| Aluminum 1.5 (0.06″) | N2 | |

| 2000W | Stainless Steel 3 (0.12″) | Ar |

| Carbon Steel 3 (0.12″) | Ar | |

| Galvanized Sheet 2.5 (0.098″) | Ar | |

| Aluminum 2.5 (0.098″) | N2 | |

| 3000W | Stainless Steel 4 (0.157″) | Ar |

| Carbon Steel 4 (0.157″) | Ar | |

| Galvanized Sheet 3.5 (0.137″) | Ar | |

| Aluminum 3 (0.12″) | N2 | |

| 4000W | Stainless Steel 5 (0.196″) | Ar |

| Carbon Steel 5 (0.196″) | Ar | |

| Galvanized Sheet 4.5 (0.177″) | Ar | |

| Aluminum 4 (0.156″) | N2 | |

| 6000W | Stainless Steel 6 (0.236″) | Ar |

| Carbon Steel 6 (0.236″) | Ar | |

| Galvanized Sheet 5.5 (0.216″) | Ar | |

| Aluminum 5 (0.0196″) | N2 | |

| 2000W + 4000W (6000W) | Stainless Steel 6 (0.236″) | Ar |

| Carbon Steel 6 (0.236″) | Ar | |

| Galvanized Sheet 5.5 (0.216″) | Ar | |

| Aluminum 5 (0.0196″) | N2 | |

| 4000W + 4000W (8000W) | Stainless Steel 8 (0.314″) | Ar |

| Carbon Steel 8 (0.314″) | Ar | |

| Galvanized Sheet 7 (0.275″) | Ar | |

| Aluminum 7 (0.275″) | N2 | |

| 6000W + 6000W (12000W) | Stainless Steel 11 (0.433″) | Ar |

| Carbon Steel 11 (0.433″) | Ar | |

| Galvanized Sheet 10 (0.393″) | Ar | |

| Aluminum 9 (0.354″) | N2 |

Read all of the above on Handheld laser welding machine introduction To give you a better understanding of the Handheld laser welding machine, take the 1000 watt Handheld laser welding machine as an example to show you the details of the Handheld laser welding machine’s configuration, composition, Operation Principle, scope of application and purchase details:

Name of equipment:Hand-held laser welding machine

Type of machine: JTC-SC-1000W

Notes

Technical Parameters

| 1 | Name of equipment | Hand-held optical fiber laser welding machine |

| 2 | Laser power | 1000W |

| 3 | Laser wavelength | 1070 NM |

| 4 | Fiber length | Standard 8-10M maximum 15M |

| 5 | Mode of operation | Continuous/modulation |

| 6 | Speed range of welding machine | 0~120 mm/s |

| 7 | Cooling machine | Industrial Constant temperature water tank |

| 8 | Industrial Constant temperature water tank | 15~35 ℃ |

| 9 | Temperature range of working environment | < 70% no condensation |

| 10 | Recommended welding thickness | 0.5-5mm |

| 11 | Welding gap requirements | ≤0.5mm |

| 12 | Operating Voltage | AV220V |

Equipment configuration

| No. | Name | Qty | Unit | Notes |

| 1 | Laser Source | 1 | Set | Fiber Laser (optional) |

| 2 | Laser water chiller | 1 | Set | Shanghai QuanGu Refrigeration Air-condition |

| 3 | Sheet metal | 1 | Set | Optional |

| 4 | Welding Gun | 1 | Set | Swing type hand gun/double swing type hand gun (optional) |

| 5 | Protective Lens | 5 | piece | Imported Quartz 20X2 |

| 6 | Tool box | 1 | Set | Standard fitting |

| 7 | Equipment Operation Manual | 1 | Piece | Standard fitting |

| 8 | Factory nameplate | 1 | Piece | Standard fitting |

| 9 | Equipment installation and commissioning list | 1 | Piece | Laser Source Standard |

| 10 | machine Acceptance Certificate | 1 | Piece | Laser Source Standard |

| 11 | Switching power supply | 1 | Set | Ming Wei, Taiwan |

| 12 | Swing Motor power supply | 1 | Set | Hengfu power supply |

| 13 | Creepage switch | 1 | Piece | Zhejiang CHNT |

| 14 | COPPERHEADS | 5+5 | Piece | Y type and wire feeding copper nozzle |

| 15 | Protective Glasses | 1 | Set | Anti-radiation glasses |

| 16 | Gloves | 2 | Set | Cotton |

| 17 | Backup switch | 1 | Piece | Hand-held metal switch |

| 18 | Wire Feeder | 1 | Set | Digital step |

Equipment advantage:

Pure hand-held laser welding machine is a hand-held welding joint, optical fiber connected to the hand-held welding joint, and then realize various welding products. The advantage of the hand-held laser welding machine is that it can weld the products with larger size and longer welding length, such as water tank and stainless steel kitchen cabinet without putting these products on the worktable. In addition to repair large mold, large-scale machinery can also achieve long-distance welding, do not take down the product can be welded. It has the advantages of simple operation, beautiful welding seam, fast welding speed and no consumables. It can perfectly replace the traditional Argon arc welding and electric welding in thin stainless steel plate, iron plate, galvanized steel plate and other metal materials. Hand-held laser welding machine can be widely used in kitchen and bathroom, elevator, shelves, ovens, stainless steel doors and windows guardrail, distribution box, stainless steel home and other industries complex irregular welding procedures.

Product Feature:

Weld penetration data

| Stainless steel | Laser Source(W) | Power(W)

| Speed(mm/s)

| Frequency(kHz) | Focus(mm) |

| 1mm | 500 | 260 | 800 | 5 | +2 |

| 1.5mm | 500 | 340 | 750 | 5 | +2 |

| 2mm | 1000 | 600 | 800 | 5 | +2 |

| 2.5mm | 1000 | 730 | 700 | 5 | +2 |

| 3mm | 1000 | 860 | 720 | 5 | +3 |

|

|

| Aluminium | Laser source(W) | Power(W) | Speed(mm/s) | Frequency(kHz) | Focus(mm) |

| 1mm | 500 | 480 | 700 | 20 | +1 |

| 1.5mm | 1000 | 560 | 800 | 20 | +1 |

| 2mm | 1000 | 780 | 800 | 20 | +2 |

| 2.5mm | 1000 | 920 | 800 | 20 | +2 |

| 3mm | 1500 | 1150 | 800 | 20 | +2 |

| Brass | Laser source(W) | Power(W) | Speed(mm/s) | Frequency(kHz) | Focus(mm) |

| 1mm | 1000 | 900 | 600 | 30 | +3 |

| 1.5mm | 1500 | 1100 | 600 | 30 | +4 |

| 2mm | 1500 | 1350 | 500 | 30 | +4 |

| 2.5mm | 2000 | 1600 | 500 | 30 | +5 |

| 3mm | 2000 | 1850 | 500 | 30 | +6 |

| Red Copper | Laser source(W) | Power(W) | Speed(mm/s) | Frequency(kHz) | Focus(mm) |

| 1mm | 1000 | 650 | 600 | 30 | 0 |

| 1.5mm | 1000 | 850 | 600 | 30 | 0 |

| 2mm | 1500 | 1100 | 500 | 30 | 0 |

| 2.5mm | 1500 | 1400 | 500 | 30 | 0 |

| 3mm | 2000 | 1750 | 500 | 30 | 0 |

| Carbon Steel | Laser Source(W) | Power(W) | Speed(mm/s) | Frequency(kHz) | Focus(mm) |

| 1mm | 500 | 300 | 500 | 20 | 0 |

| 1.5mm | 500 | 370 | 500 | 20 | 0 |

| 2mm | 500 | 480 | 600 | 20 | +1 |

| 2.5mm | 1000 | 600 | 600 | 20 | +1 |

| 3mm | 1000 | 760 | 700 | 20 | +2 |

| Galvanized sheet | Laser Source(W)

| Power(W)

| Speed(mm/s)

| Frequency(kHz)

| Focus(mm)

|

| 1mm | 500 | 320 | 600 | 20 | 0 |

| 1.5mm | 500 | 460 | 600 | 20 | +1 |

| 2mm | 1000 | 600 | 500 | 20 | +2 |

| 2.5mm | 1000 | 800 | 700 | 20 | +3 |

| 3mm | 1000 | 960 | 650 | 20 | +3 |

Can Laser welding take wire feed? Re:Yes, 0.8-1.0 for 1000 watts and 0.8-1.2 for 1500 watts

| Contrast item | Conventional Welding | Laser welding | Continuous laser welding |

| Heat input to the workpiece | Very High | Low | Low |

| Deformation of the work piece, Bit Edge | Big | Small | Small |

| Bonding strength with base metal | common | good | Excellent |

| Follow-up | Sanding | No or little polishing is required | No or little polishing is required |

| Welding speed | common | Argon arc welding more than twice | Argon arc welding more than twice |

| Applicable material | Stainless steel, carbon steel, galvanized sheet | Stainless steel, carbon steel, galvanized sheet | Stainless steel, carbon steel, galvanized sheet |

| Consumables | more consumables. | Few consumables | Few consumables |

| Operational difficulty | Complicated | General | simple |

| Operator security | It’s not safe | Safety | Safety |

| Environmental Impact | Not environmentally friendly | Environmentally friendly | Environmentally friendly |

| Welding fault tolerance | Okay | not good | Okay |

| Swing welding | None | None | Yes |

| Adjustable spot width | None | None | Yes |

| Comparison of welding quality | Poor | common | Excellent |

Advantage of using equipment

1、Novice can quickly learn to operate, for you to save expensive technical labor costs! This product operation is simple and convenient, raw and experienced hands can be on the machine operation, for you to solve the technical talent difficult to recruit, technical talent high wages!

2、The worker is efficient and does not work tired! Hand-held rapid positioning welding, do not need to move the workpiece, just move the hand-held welding joint can be fast welding, high working efficiency.

3、Clean work, improve the image of the company! Hand-held laser welding machine in work, welding smokeless, no strong light, ultra-low noise, no matter the size of the workpiece, how complex can be welded, welding precision, meticulous.