China jewelry Laser welding machine

- Using air-cooled fiber laser

- Small in size and light in weight

- No water, no frost

- All in one screen

- Industria CCD tracking

- Longer Service Life

- Free Maintenance

- Easy Operation

Jewelry Laser welding machine Hot Sale

Jewelry Laser welding machine Hot Sale can meet any of your welding needs.

Jewelry laser welding machine, for jewelry products mainly used in gold and silver jewelry repair hole and spot welding sand hole. Welding of gold and silver jewelry.

It is mainly used for repairing holes in gold and silver jewelry, spot welding sand holes, and repair welding. It is suitable for gold, silver, platinum, stainless steel, titanium, and other multi-metals and their alloy materials, it can also be used for the welding of the dental filling sand holes and small precision devices such as battery nickel strip, ic lead wire, watch hairpin, picture tube, electron gun assembly and etc.

It is widely used in precision casting welding of various metal materials, such as jewelry, false teeth, clocks and watches, medical, instrument, electronic, mechanical die processing, automobile, etc. the utility model is especially suitable for welding the holes of gold and silver jewelry, the sand holes of spot welding, the repair seam lines, the claw feet of inlaid parts, etc.

Features

- The core part “laser concentrator” adopts imported ceramic or metal reflective concentrator, which has more stable performance, longer service life, high efficiency, and economical processing scheme

- The welding speed is fast, the welding efficiency is obviously improved, the welding time of a single workpiece is greatly shortened, and the investment return period is accelerated for customers.

- High welding quality, beautiful weld, and base metal strength, without secondary processing, effectively improve the yield.

- Welding refractory materials, especially suitable for micro-small parts, jewelry precision welding.

- The special plane custom-made ability is strong, can according to the customer request tailor-made special model.

Applications

It is widely used in precision casting welding of hardware composed of all kinds of metal materials, such as jewelry, dentures, watches and clocks, medical treatment, instrumentation, electronics, mechanical mold processing, automobile and other industries, especially suitable for repairing holes in gold and silver jewelry. Spot welding, repair seams and embedded parts claw feet and other welding.

Introduction of jewelry welding machine

1. The energy, pulse width, frequency, and spot size can be adjusted in a wide range to achieve a variety of welding effects. The parameters are adjusted by the control rod in the closed cavity, which is simple and efficient.

2. Using the most advanced automatic shading system in the world, it eliminates irritation to the eyes during working hours and has the ability to work continuously for 24 hours.

3. The working performance of the whole machine is stable, maintenance-free within 10000 hours, humanized design, in line with ergonomics, long hours of work without fatigue.

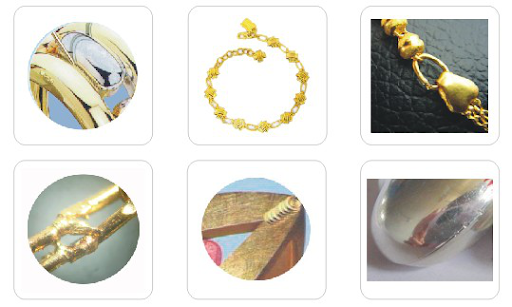

Welding Samples Under Different Laser Working Modes

Jewelry laser welding machine is suitable for laser welding of gold jewelry, laser welding of silver jewelry, laser spot welding of titanium alloy jewelry, laser spot welding of stainless steel jewelry, laser spot welding of all kinds of jewelry, and manual laser welding of small metal parts. the ergonomic design of the whole machine is suitable for the jewelry laser welding industry, professional appearance design, core components imported, stable performance, suitable for long-time continuous work. The internal space is large, which is convenient for the placement of laser spot welding tools and fixtures.

The Features of Double Wobble Laser Gun

According to the different welding processes, customers can change the corresponding nozzle (yin angle, copper nozzle, Yang angle copper nozzle, wire delivery copper nozzle).

The focal length of the screw tube can be adjusted with a value of ± 10

6 Different Laser Control Modes.

1.Dot.

2.Line.

3.Circle.

4.Double-Circle.

5.Triangles.

6.Double Triangles.

Parameter characteristics of Jewelry Laser Welding Machine

Jewelry laser spot welding machine is widely used in aviation, aerospace, sporting goods, jewelry, golf head, medical equipment, aluminum alloy denture, instrumentation, electronics, mechanical processing, automobile and other industries, especially for repairing holes in gold and silver jewelry. Spot welding seam pattern, embedded military parts and claw foot parts and other welding.

| Welding Mode | Descriptions |

|---|---|

| Dot Mode | Dot mod or we call it spot welding is a good at deep penetration welding, such as laser perforation, stich welding and cutting like a hand held laser cutter. |

| Line Mode | For butt welding, external corner welding. |

| Circle Mode | For welding thin plate (minimum 0.3mm or 0.12″) and 90 degrees corner welding. |

| Double Circle Mode | Enhanced circle mode, common use in various kinds of welding. |

| Triangle Mode | For all kinds of welding. |

| Double Triangle Mode | Enhanced triangle mode, for internal and external corner welding with nice fish scale pattern. |

Technical Parameters

Technical parameter |

|

Laser | Nd:YAG |

Maximum laser output power | 400W |

Laser wavelength | 1064nm |

Minimum Weld Pool | 0.05mm |

Welding depth | 3mm |

Pulse width | 0.5-20ms |

Pulse frequency | 1-20Hz |

power consumption | ≤16KW |

Electricity demand | 380V/Three phase/50Hz/60A |

External dimension of system(L×W×H)mm | |

Machine size | 1170×520×1080MM |

Chiller size | 400×630×800MM |

Name of equipment: Jewelry laser welding machine

Type of machine: JTC-SC-300W

Notes

Packing list of precision laser welding machine

Parts Name | Quantity and remarks |

Laser source | The 1200 laser contains internal optical elements, a set |

Power control cabinet | Each electrical equipment and laser power supply, a set |

Laser cooling circulator | Water pipe and water filter element, filter element box, one se |

Connecting cable | Six Pieces。 |

Light switch flange plate | One Piece |

Laser head adapter | One Piece |

Wrench for replacing filter element | One Piece |

Frequently Customer Enquiry

What is a jewelry laser welder and what can be done?

Jewelry laser welding machine can weld how much size of the product?

Strictly speaking, the jewelry laser welding machine can weld any shape of jewelry.

What materials can jewelry laser welding machine weld ?

Jewelry laser welding machine can weld 0.4-5.0 mm thick stainless steel, galvanized sheet, iron, copper, aluminum, and other metal materials.

Can large workpieces gap be welded by jewelry welding machine?

Yes, it can be welded.

What is the welding effect of the jewelry welding machine?

Welding effect is good: jewelry laser welding is hot fusion welding, compared to traditional welding, laser welding has a higher energy density, can achieve better welding effect, welding area heat effect is small, not easy to deformation, blackening, backtrace problem, the welding depth is big, the fusion is full, the firm is reliable, the welding seam strength achieves even surpasses the base material itself, this is ordinary welding machine can not guarantee

Does the weld need to be polished?

Welds do not need to be polished: after traditional welding, the welding point needs to be polished to ensure smooth and not rough. The jewelry laser welding just reflects the processing effect of more advantages: continuous welding, smooth no fish scale pattern, beautiful no scars, less follow-up grinding process.

What are the consumables for a jewelry welding machine?

Welding consumables: most people’s impression of the welding operation is “Left-hand goggles, right-hand clip wire.”. But with the jewelry laser welding machine can easily complete welding, more reduce the cost of production and processing of materials.

Is it safe to use a hand-held laser welder?

With a plurality of safety alarms, the welding nozzle is effective only when it touches the metal, automatically locks the light when the workpiece is removed, and the triggering switch is temperature-sensitive. High Security, to ensure the safety of operators during the work period.