China Pulse laser welding machine Manufacturer

- High Peak Power

- Small heat-affected area

- Spare parts are readily available

- The welding accuracy is very high

- Ideal for welding deformable materials

- Good welding effect

- Cost-effective

Solid pulse lamp pump laser welding machine

Solid pulse lamp pump laser welding machine can meet any of your repair welding needs.

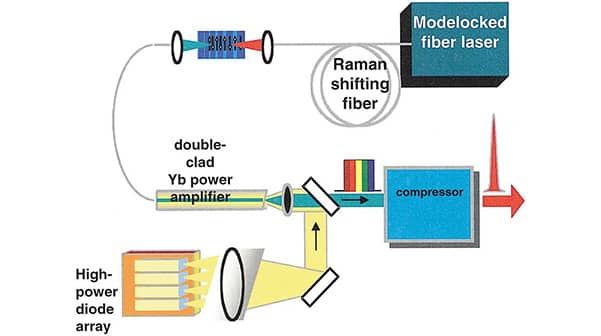

Pulse lamp pumps laser welding machine, this is the first generation of the earlier pulse laser welding machine, this is the pulse laser welding, it is generally used in the xenon lamp-pumped laser ruby crystal, and then generate laser.

Its frequency is from 1 Hz to 100 Hz, its peak power is still quite high, as this general average power of 200 watts 300 watts 400 watts 500 watts, and then the highest UH is 600 watts can not do too high.

However, its peak pulse is relatively high, therefore, this suitable for that type of welding requirement is the heat-affected zone of the very small welding process.

Features

- It is characterized by its high speed. Low cost, good welding effect, small heat-affected area, and the non-deformable workpiece surface. Wide applicability, cost-effective. The series is easy to learn and operate!

- these welders have more sophisticated and less expensive fittings, and the same set, the 400-watt model, for example, may be as small as forty thousand RMB cost, which can be made to weld watch cases and thin metal,

- This welding machine has a better function, that is, it is used for die repair, die repair welding, because its heat-affected zone is small, not as strong as continuous optical fiber, a very small amount of heat is enough, it is pulse-type spot welding, and if it is continuously welded at 20 Hz to 30 Hz, it will produce a very nice fish scale pattern.

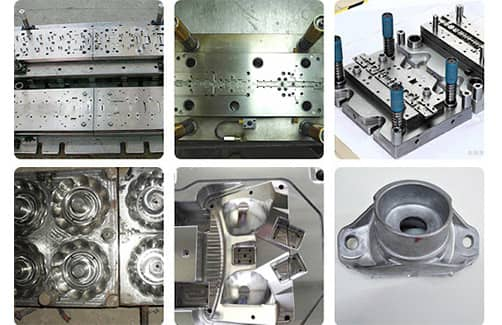

Applications

Suitable for carbon steel. Stainless steel. Aluminum. Copper. Nickel. Titanium. Welding of silver, gold, platinum, and other metals and their alloys. Widely used in batteries. Solar energy. Mobile phone communication. Glasses industry, mold. Electronic appliance. instrument. Gold and silver jewelry. Medical devices. Aerospace. Automobile industry and so on!

Introduction of Solid pulse lamp laser welding machine

1. The output laser is stable, the beam quality is high, the focused energy is concentrated, and the welding depth is deep.

2. The size of the solder joint can be adjusted, and the special man-machine interface control can realize the automatic welding after programming. Output light angle can be adjusted, can cope with multi-angle, abnormal workpiece welding.

3. Water cooling system can be automatically protected, automatic temperature detection, the whole machine is simple to operate.

4. The machine warranty period of 12 months, to provide home and remote network assistance, telephone, etc.

5. Can be equipped with a variety of angle nozzles to meet different product welding needs.

Welding Samples Under Different Laser Working Modes

It provides the condition for more precise welding, the flexible transmission non-contact welding is applied to the hard-to-reach parts of the welding, with more flexibility, the CCD camera monitoring system is selected to facilitate observation and precise positioning, and the welding spot energy is evenly distributed, it is suitable for spot welding, spot welding of various components and seam welding of thin plate with seam width less than 1 mm.

The Features of Solid pulse lamp pump laser welding machine

This is a new generation of welding technology, is a more economical way of welding, this equipment is to use electrical energy for transmission to the laser xenon lamp inside, using light to stimulate laser crystal to produce laser, this conversion efficiency is relatively low compared to optical fiber, 3%-3.5% conversion efficiency, equivalent to 100 watts in and out of 3 watts to 3.5 watts of laser power, it has the advantage of using accessories are sufficient, but also relatively cheap, the same set, say a 400-watt model, which might be in the range of forty thousand, could be made to weld watch cases and thin metal.

6 Different Laser Control Modes.

1.Dot.

2.Line.

3.Circle.

4.Double-Circle.

5.Triangles.

6.Double Triangles.

Applications of Solid pulse lamp pump laser welding machine

Table of basic parameters

|

Product name: | Complete equipment of laser welding machine | ||||||

| Model No.: | JTC-YAG500A | |||||||

| Product description: | Medium-sized laser welding system, programmable control. | |||||||

| The output laser is stable, the beam quality is high, the focus point energy is concentrated, the welding depth is deep, the welding spot size can be adjusted, the special man-machine interface control can realize the programmed automatic welding. Output light angle can be adjusted, can cope with multi-angle, abnormal workpiece welding. Water cooling system can automatically protect, automatic temperature detection, the whole machine operation brief introduction. The machine warranty period of 12 months, to provide domestic home and remote network assistance, telephone etc. | ||||||||

| Table of basic parameters | ||||||||

| Parameter name | Numerical value | Unit | Notes | Parameter name | Numerical value | Unit | Notes | |

| Laser wavelength | 1064 | mm | Central wavelength | Maximum monopulse | Energy | 110J | Optional 80J.150J | |

| Laser Power | 500 | W | Average power | Focusing spot | 0.2-2.0 | mm | Circular shape | |

| Pulse frequency | 1-100 | HZ | Custom-made 1-300、1-500 | Laser focal length | 120 | mm | Optional 100/200 | |

| Pulse width | 0.5-20 | ms | Custom-made 0.1-20 | Observation system | CCD | A set | High-filter anti-shake | |

| Protective gas | 5 Atmospheric Argon | Atmospheric pressure | Optional oxygen or air | Trigger mode | Manual, signal | Optional | ||

| Working Table | Electric table, stroke 200mm * 200mm, plus rotating c axis, plus z axis | Control appliance | Schneider, all of it | |||||

| Operational control | CNC2000 multi-axis motion control software (including PC software) | Electricity demand | AC380V 50/60HZ Three phase four wire system | |||||

| Previewing | Optional red laser indication | Rated power | Less than 16 kw | |||||

| Cooling system | High-strength refrigerating unit, controllable high-precision water temperature display | Supply wire | It is recommended that the conductor cross-sectional area be greater than or equal to 6 mm2 | |||||

| Cooling medium | Deionized water, distilled water, pure water, resistivity greater than 10 Megohm | Running time | It can run continuously for more than 8 hours | |||||

Frequently Customer Enquiry

Most frequent questions and answers about the handheld laser welding machine

What is a Solid pulse lamp pump laser welding machine and what can be done?

This is the solid pulse lamp pump laser welder, which is the first generation of the earlier pulse laser welder,is used for die repair, die repair welding!

Solid pulse lamp pump laser welding machine can weld how much size of the product?

Any mobile and non-mobile metal products can be welded

What materials can optical fiber laser hand-held welding machine weld ?

Stainless steel. Aluminum. Copper. Nickel. Titanium. Welding of silver, gold, platinum, and other metals and their alloys. Widely used in batteries. Solar energy. Mobile phone communication. Glasses industry, mold. Electronic appliance. instrument. Gold and silver jewelry. Medical devices. Aerospace. Automobile industry

Can large workpieces gap be welded by hand-held welding machine?

Yes, it can be welded, This welding machine is easy to move, can be moved to any need to weld the workpiece to carry out welding.

What is the welding effect of the Solid pulse lamp pump laser welding machine?

Welding is mainly to the thin plate, especially the thin deformation materials, but also some stainless steel parts of precision parts heat-affected zone and need a certain high-power peak of the workpiece welding to need this type of welding.

Does the weld need to be polished?

Welds do not need to be polished: after traditional welding, the welding point needs to be polished to ensure smooth and not rough. The Pulse laser welding just affects a very small area, no need to be polished, The weld itself is very smooth already.

What are the consumables for a Solid pulse lamp pump laser welding machine?

This is the first generation of welding technology, a more economical way of welding, this equipment is to use electrical energy for transmission to the laser xenon lamp inside, using light to stimulate laser crystal to produce laser, this conversion efficiency is relatively low compared to optical fiber, it is only 3%-3.5% conversion efficiency.

Is it safe to use a Solid pulse lamp pump laser welding machine?

With a plurality of safety alarms, the welding nozzle is effective only when it touches the metal, automatically locks the light when the workpiece is removed, and the triggering switch is temperature-sensitive. High Security, to ensure the safety of operators during the work period.